What is the Manufacturing Process of Honda Small Car Series 20W?

Introduction

Honda has long been recognized as a leading automotive manufacturer, known for its commitment to quality, innovation, and sustainability. Among its diverse lineup, the Honda Small Car Series 20W stands out as a compact vehicle that combines efficiency with modern design. Understanding the manufacturing process of this series not only sheds light on Honda's operational excellence but also highlights the intricate steps involved in bringing a vehicle from concept to the consumer.

1. Overview of the Honda Small Car Series 20W

The Honda Small Car Series 20W is designed to cater to urban drivers seeking a compact yet versatile vehicle. This model is significant in Honda's lineup due to its balance of performance, fuel efficiency, and affordability. Key features include a fuel-efficient engine, advanced safety systems, and a spacious interior that maximizes comfort for both drivers and passengers. The target market primarily consists of young professionals and small families who prioritize practicality and cost-effectiveness in their vehicle choice.

2. Pre-Manufacturing Phase

2.1 Research and Development

The journey of the Honda Small Car Series 20W begins with extensive research and development. This phase involves conceptualization and design, where engineers and designers collaborate to create a vehicle that meets market demands. Prototyping and testing follow, allowing Honda to refine the design based on performance metrics and consumer feedback. This iterative process ensures that the final product aligns with Honda's high standards and customer expectations.

2.2 Supply Chain Management

Effective supply chain management is crucial for the success of the manufacturing process. Honda sources materials and components from a network of trusted suppliers, ensuring that each part meets stringent quality standards. Partnerships with suppliers are vital, as they provide the necessary resources while maintaining cost efficiency. This collaborative approach helps Honda mitigate risks associated with supply chain disruptions.

2.3 Production Planning

Production planning is the next step, where Honda sets clear production goals and timelines. This phase involves designing the facility layout to optimize workflow and resource allocation. By carefully planning the production process, Honda can enhance efficiency and reduce waste, ultimately leading to a more sustainable manufacturing operation.

3. Manufacturing Process

3.1 Stamping

The manufacturing process begins with stamping, where large sheets of metal are shaped into body panels. This process utilizes advanced stamping presses that apply immense pressure to form the metal into precise shapes. The accuracy of this step is critical, as it lays the foundation for the vehicle's structure.

3.2 Welding

Once the body panels are stamped, they undergo welding to create a cohesive structure. Honda employs various welding techniques, including spot welding and MIG welding, to ensure the integrity of the vehicle. The importance of structural integrity cannot be overstated, as it directly impacts the safety and durability of the car.

3.3 Painting

After welding, the vehicle moves to the painting stage. This process involves multiple steps, including surface preparation, priming, and applying the final paint coat. Honda places a strong emphasis on environmental considerations during this phase, utilizing eco-friendly paints and advanced techniques to minimize waste. Quality control measures are also implemented to ensure a flawless finish.

3.4 Assembly

The assembly process is where all components come together to form the final vehicle. This step is highly organized and often involves a combination of manual labor and automation. Robotics play a significant role in enhancing efficiency and precision during assembly, allowing Honda to maintain high production standards while reducing the risk of human error.

3.5 Quality Control

Quality control is an ongoing process throughout manufacturing. Honda implements rigorous inspection processes at various stages, ensuring that each vehicle meets safety and performance standards. Testing includes everything from checking the fit and finish of components to conducting safety tests that simulate real-world driving conditions.

4. Post-Manufacturing Phase

4.1 Final Inspection and Testing

Once assembly is complete, each vehicle undergoes a final inspection and testing phase. This comprehensive evaluation includes road tests to assess performance, handling, and comfort. Emissions testing is also conducted to ensure compliance with environmental regulations. Only after passing these tests is the vehicle deemed ready for the market.

4.2 Packaging and Shipping

After passing final inspections, the vehicles are prepared for packaging and shipping. Honda employs efficient logistics strategies to transport vehicles to dealerships worldwide. This phase is crucial for ensuring that the vehicles arrive in pristine condition and are available to consumers in a timely manner.

4.3 After-Sales Support

Honda's commitment to quality extends beyond the sale of the vehicle. After-sales support includes warranty services and maintenance options, ensuring that customers have access to the necessary resources for vehicle upkeep. Customer feedback is actively sought and analyzed, allowing Honda to make continuous improvements to its products and services.

5. Sustainability and Innovation

5.1 Eco-Friendly Manufacturing Practices

Honda is dedicated to sustainability, and this commitment is reflected in its manufacturing practices. The company prioritizes the use of sustainable materials and energy-efficient production methods. By reducing waste and minimizing environmental impact, Honda aims to create a more sustainable future for the automotive industry.

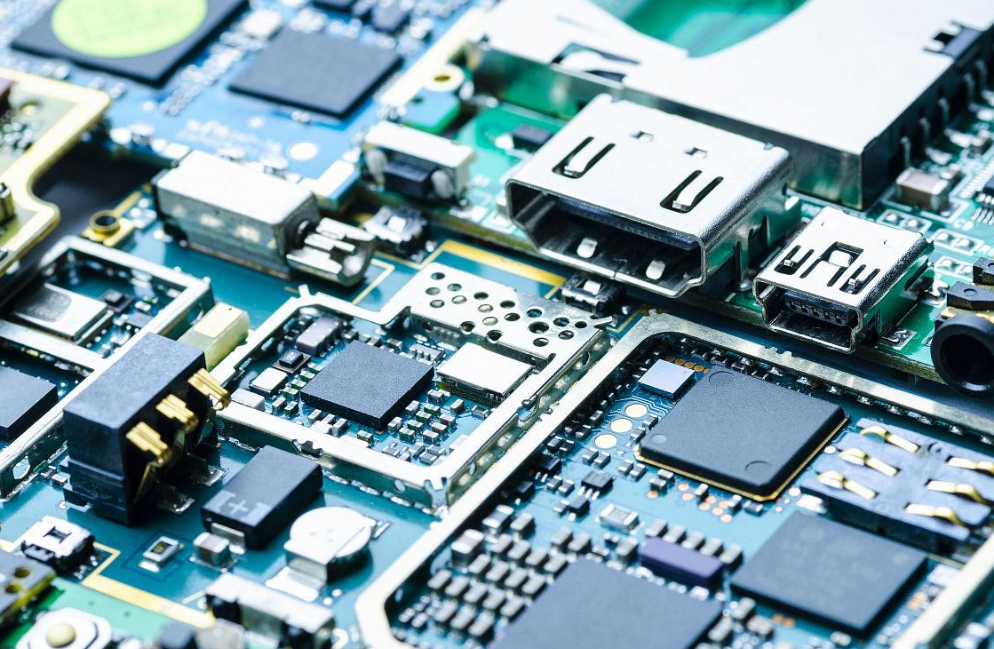

5.2 Technological Innovations

Technological innovations play a pivotal role in Honda's manufacturing process. The integration of advanced technologies, such as artificial intelligence and the Internet of Things (IoT), enhances efficiency and quality control. These innovations not only streamline production but also pave the way for future trends in automotive manufacturing, such as increased automation and smart manufacturing systems.

6. Conclusion

The manufacturing process of the Honda Small Car Series 20W is a testament to Honda's commitment to quality, efficiency, and innovation. From the initial stages of research and development to the final inspection and after-sales support, each step is meticulously planned and executed. As Honda continues to evolve in the automotive industry, its focus on sustainability and technological advancements will undoubtedly shape the future of vehicle manufacturing.

In summary, understanding the manufacturing process of the Honda Small Car Series 20W provides valuable insights into the complexities of automotive production. It highlights the importance of quality and efficiency in delivering a product that meets the needs of consumers while adhering to environmental standards. As the automotive landscape continues to change, Honda's dedication to excellence will remain a driving force in its success.

References

- Honda Motor Co., Ltd. (2023). Corporate Information.

- Automotive Manufacturing Processes: A Comprehensive Guide.

- Sustainable Practices in the Automotive Industry: Trends and Innovations.

- Quality Control in Automotive Manufacturing: Best Practices.